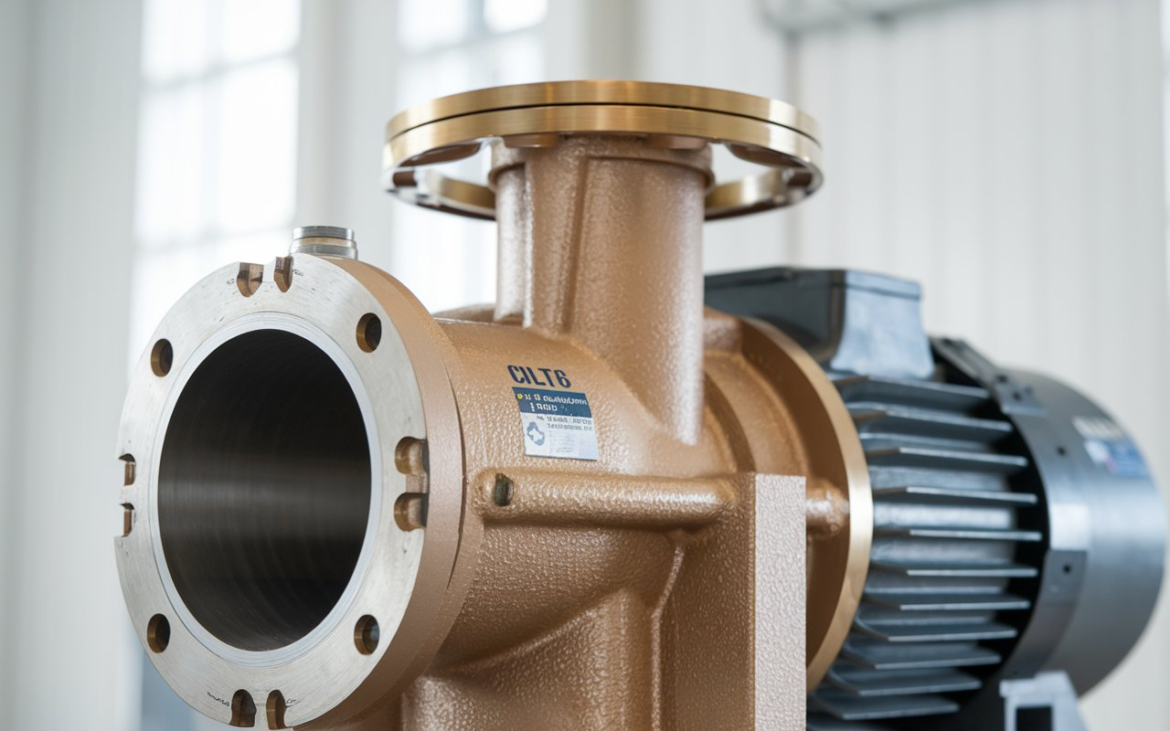

The Allweiler CLT6 pump no wear ring is changing the way we think about fluid handling. This special pump stands out because it doesn’t have a wear ring, a part that often causes problems in other pumps. By removing this component, the Allweiler CLT6 pump helps make things run smoother and last longer. This is great news for industries that need reliable pumps without the hassle of constant maintenance.

With the Allweiler CLT6 pump no wear ring, you get a machine that works efficiently while saving you time and money. Fewer parts mean less chance of things breaking down, so businesses can focus on what they do best. This innovative design is perfect for any company looking to improve their pumping systems and keep things flowing smoothly.

Understanding the Allweiler CLT6 Pump No Wear Ring

The Allweiler CLT6 pump no wear ring is a special type of pump that stands out because it does not use a wear ring. Many pumps have wear rings to help them work properly, but this pump is different. By eliminating the wear ring, it has fewer parts that can break. This means it is more reliable and can work longer without needing repairs.

In addition, this design helps reduce friction inside the pump. Friction is what happens when parts rub against each other, which can cause wear and tear. With less friction, the Allweiler CLT6 pump can operate more smoothly. This makes it a great choice for industries that need pumps that won’t let them down.

Another key point is that the Allweiler CLT6 pump is easier to maintain. Without a wear ring, there is less to check and replace. Businesses can spend less time on maintenance and more time on their work. This is why many companies are choosing this pump for their fluid handling needs.

The innovative design shows that Allweiler is serious about improving pump technology. Their focus on efficiency and reliability means this pump is built for the future. Industries looking for dependable solutions can trust the Allweiler CLT6 pump to meet their needs.

Why the Allweiler CLT6 Pump No Wear Ring is a Game Changer

The Allweiler CLT6 pump no wear ring is a game changer for many reasons. First, it helps save energy. Since it has less internal friction, it doesn’t need as much power to run. This can lead to lower energy bills, which is great for businesses trying to cut costs. Energy savings can really add up over time.

Second, this pump is very durable. The absence of a wear ring means there are fewer parts to wear out. This results in a longer lifespan for the pump, which can be a big advantage in industries where equipment must work for years. Companies can invest in this pump knowing it will last a long time without needing frequent replacements.

- Benefits of the Allweiler CLT6 Pump:

- Energy Efficiency: Uses less power.

- Durability: Lasts longer without needing repairs.

- Low Maintenance: Fewer parts to check.

Additionally, the Allweiler CLT6 pump is versatile. It can be used in different industries like chemical processing, water treatment, and more. Its ability to handle various fluids makes it a flexible choice for companies. This adaptability means it can fit into many applications without any issues.

How the Allweiler CLT6 Pump No Wear Ring Works

The design of the Allweiler CLT6 pump no wear ring is simple yet effective. Instead of having a wear ring, it uses a unique sealing system. This keeps the fluids contained while reducing friction at the same time. The result is a pump that runs smoothly and efficiently.

Moreover, the Allweiler CLT6 pump features advanced materials that enhance its performance. These materials can withstand different types of fluids, whether they are thick or thin. As a result, the pump can operate effectively in various environments, meeting the needs of different industries.

- How It Works:

- Sealing System: Keeps fluids contained without a wear ring.

- Advanced Materials: Withstands various fluids.

- Smooth Operation: Reduces friction for better performance.

To sum up, the way the Allweiler CLT6 pump is built helps it achieve high efficiency. Its innovative design ensures that it can meet the challenges of modern industries. Companies looking for effective pumping solutions will find that this pump is a reliable choice.

The Benefits of Using the Allweiler CLT6 Pump No Wear Ring

Using the Allweiler CLT6 pump no wear ring comes with many benefits. One of the main advantages is the cost savings. Since the pump needs less maintenance and lasts longer, companies can save money on repairs and replacements. This makes it a smart investment for any business.

Another benefit is improved efficiency. The design of the Allweiler CLT6 pump means it can move fluids faster and more effectively. When pumps work well, it can lead to increased productivity for the entire operation. Businesses can produce more with less effort, which is always a good thing.

- Benefits of the Allweiler CLT6 Pump:

- Cost Savings: Reduces repair costs.

- Improved Efficiency: Moves fluids quickly.

- Increased Productivity: Helps businesses do more.

Additionally, this pump is eco-friendly. Because it uses less energy, it can help reduce a company’s carbon footprint. Many businesses today are looking for ways to be more sustainable. The Allweiler CLT6 pump supports these efforts by being an environmentally responsible choice.

Simplifying Maintenance with the Allweiler CLT6 Pump No Wear Ring

Maintaining the Allweiler CLT6 pump no wear ring is much simpler than traditional pumps. This is because it doesn’t have the wear ring, which often requires frequent checks and replacements. With fewer parts to worry about, operators can spend less time on maintenance tasks.

Regular maintenance can be a hassle for many companies. It can lead to downtime, which means less production and higher costs. The Allweiler CLT6 pump eliminates many of these issues. This means businesses can keep their operations running smoothly without interruptions.

- Maintenance Simplified:

- Fewer Parts: Less to check and replace.

- Reduced Downtime: Keeps production flowing.

- Less Hassle: Operators can focus on important tasks.

In conclusion, the Allweiler CLT6 pump no wear ring offers an easier maintenance experience. This allows companies to operate more efficiently and effectively. As a result, they can achieve their goals without worrying about constant upkeep of their pumps.

Conclusion

The Allweiler CLT6 pump no wear ring is a fantastic choice for many businesses. It helps save money, works efficiently, and is easy to maintain. With fewer parts to check, companies can spend more time on important tasks instead of fixing pumps. This pump is built to last, making it a smart investment for any industry that needs reliable fluid handling.

Moreover, this pump is also good for the environment. It uses less energy and produces less waste, which is great for companies that want to be eco-friendly. Overall, the Allweiler CLT6 pump no wear ring is a powerful tool that can help businesses run better while caring for our planet.

FAQs

Q: What is the Allweiler CLT6 pump no wear ring?

A: It is a special pump designed without a wear ring, making it more efficient and easier to maintain.

Q: How does the Allweiler CLT6 pump save money?

A: It has lower maintenance costs and energy consumption, helping businesses save on bills.

Q: Is the Allweiler CLT6 pump durable?

A: Yes, it is built to last longer because it has fewer parts that can wear out.

Q: What types of fluids can the Allweiler CLT6 pump handle?

A: This pump can handle different fluids, making it versatile for various industries.

Q: Why is the Allweiler CLT6 pump eco-friendly?

A: It uses less energy and reduces waste, which helps companies lessen their impact on the environment.

Q: How can I maintain the Allweiler CLT6 pump?

A: Maintenance is simple because there are fewer parts to check, reducing downtime and effort needed.