In industries such as oil and gas, chemical processing, and even food production, maintaining a clean and efficient pipeline system is critical to ensuring smooth operations and reducing costs. One of the most effective ways to achieve this is through the use of pigging application. Pigging is the process of sending a device known as a “pig” through a pipeline to clean, inspect, or maintain the pipeline’s interior. In this article, we will explore the various pigging application, their significance in different industries, and the benefits they bring to pipeline operations.

What Is Pigging?

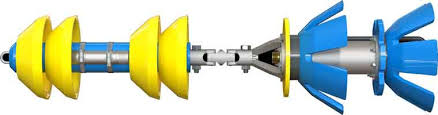

Pigging refers to the process of using a device, commonly known as a “pig,” to move through the pipeline. These pigs are typically cylindrical and designed to travel along the interior of the pipeline, performing various tasks such as cleaning, inspecting, and maintaining the pipeline. The pigs are launched into the pipeline using a device called a pig launcher, which is connected to the pipeline. As the pipeline contents (usually liquid or gas) flow, they propel the pig through the system.

Pigging is commonly used for cleaning the inner walls of the pipeline by removing unwanted materials like wax, rust, corrosion, scale, and debris. In addition to cleaning, pigs are also used for other applications such as inspecting pipeline integrity, separating pigging application different fluids within the pipeline, and even ensuring the smooth transportation of products like oil or natural gas.

Common Pigging application

The flexibility and versatility of pigging application make them a critical tool for maintaining pipeline systems. Here are some of the most common applications where pigging is used:

1. Pipeline Cleaning

One of the most common uses of pigging is to clean the pipelines. Over time, pipelines can accumulate unwanted materials like scale, rust, wax, and debris. These substances can reduce the efficiency of the pipeline, block the flow of materials, and even damage the pipeline over time. Pigging application are designed to remove these substances effectively and efficiently.

Cleaning pigs, which may be equipped with brushes, scrapers, or foam, travel through the pipeline to scrape off or loosen buildup from the pipeline walls. Regular use of cleaning pigs helps maintain the smooth operation of the pipeline, preventing blockages and enhancing the flow of materials.

2. Pipeline Inspection

Pipeline inspection is another crucial pigging application. These pigs are designed to carry inspection equipment, such as ultrasonic sensors or cameras, to evaluate the condition of the pipeline. This type of pigging, known as “smart pigging,” helps detect potential issues such as corrosion, cracks, or other forms of damage that might otherwise go unnoticed.

By sending a smart pig through the pipeline, operators can gather critical data about the internal structure of the pipeline without having to dig up sections or shut down operations. This non-invasive inspection method reduces downtime, minimizes costs, and allows for early detection of potential problems, which can be addressed before they turn into major issues.

3. Product Separation

In some industries, it is necessary to transport multiple products through the same pipeline. For example, in the oil and gas industry, pipelines are often used to transport different types of crude oil, chemicals, or liquids. Pigging application are used to separate these products effectively.

A pig can be used to isolate different types of products within the pipeline, ensuring that each product remains uncontaminated by the others. The pig acts as a separator, creating a physical barrier between different materials, which allows operators to transport multiple products without cross-contamination. This is especially important in industries like food and beverage or chemicals, where maintaining product purity is critical.

4. De-watering and Fluid Removal

In some cases, pipelines may accumulate excess water or unwanted fluids that need to be removed. This is particularly relevant in oil and gas pipelines where water can mix with the oil during transport. Using pigging application, operators can effectively remove the water and other unwanted fluids from the pipeline.

De-watering pigs, also known as “dry pigs,” are designed to push the unwanted liquids from the pipeline. These pigs are typically equipped with rubber or foam cups that seal against the pipeline walls and remove any liquid residue as they move through the system. This ensures that only the desired product remains in the pipeline, enhancing operational efficiency and preventing issues such as corrosion caused by water buildup.

5. Flow Assurance

Flow assurance is a critical concern in pipelines that transport materials like oil, natural gas, or chemicals. Over time, substances such as wax, hydrates, and paraffin can accumulate in the pipeline and hinder the flow of materials. Pigging application help manage these challenges by removing or preventing the buildup of such substances.

Specialized pigs are used to either clean the pipeline or prevent the formation of these problematic materials. For example, pigging can be used to remove wax buildup, reducing the risk of flow restrictions and ensuring that materials continue to flow smoothly through the pipeline. This type of pigging application is essential for ensuring long-term flow assurance and avoiding costly disruptions in the pipeline system.

6. Pipeline Maintenance

Pipeline maintenance is an ongoing task that requires regular monitoring and care to ensure that the pipeline remains in good working condition. Pigging application play a significant role in this process by providing continuous cleaning, inspection, and maintenance capabilities.

Regular use of cleaning pigs helps prevent buildup and maintain the pipeline’s efficiency. Smart pigs can also provide valuable data to help operators monitor the pipeline’s health and detect early signs of wear or damage. By addressing these issues proactively, operators can reduce the likelihood of costly repairs, downtime, and safety incidents.

Benefits of Pigging application

The use of pigging application brings a host of benefits to pipeline operators and industries that rely on pipeline transportation. Some of the key benefits include:

1. Cost Savings

By preventing pipeline blockages, reducing the need for repairs, and enhancing pipeline longevity, pigging application help save money. Operators can avoid costly shutdowns, minimize the risk of major pipeline failures, and reduce the need for manual labor or expensive cleaning methods. Pigging also helps avoid the cost of replacing sections of the pipeline, as it reduces the chances of long-term damage.

2. Increased Efficiency

Pigging improves the efficiency of the pipeline by ensuring that it remains free from obstructions and buildup. By maintaining smooth flow, operators can reduce energy consumption and improve the overall throughput of the pipeline. In industries where speed and efficiency are essential, pigging plays a critical role in keeping the pipeline system running at its optimal capacity.

3. Safety Enhancement

By maintaining a clean and well-maintained pipeline, pigging application reduce the risk of leaks, ruptures, and other safety hazards. This is especially important when transporting hazardous materials such as oil, gas, or chemicals. Regular pigging ensures that the pipeline remains structurally sound and free from obstructions that could lead to dangerous situations.

4. Environmental Protection

In industries that transport potentially harmful materials, environmental protection is a top priority. By preventing leaks, reducing the risk of spills, and maintaining pipeline integrity, pigging application help protect the environment. Regular pigging reduces the chances of hazardous materials escaping into the surrounding environment, ensuring that operations are both safe and environmentally friendly.

Conclusion

In summary, pigging application are an essential part of maintaining and optimizing pipeline systems across a wide range of industries. Whether used for cleaning, inspection, product separation, or flow assurance, pigging provides critical benefits such as cost savings, increased efficiency, enhanced safety, and environmental protection. By regularly using pigs, operators can ensure the smooth and safe operation of their pipeline systems, reducing the risk of damage and maximizing performance. As pipelines continue to be a vital part of modern infrastructure, the importance of pigging application will only continue to grow.